Composite semi-products

Composite semi-products

Skills

- Supply

- Storage

- Cutting

- Traceability

- Kitting

- Logistics

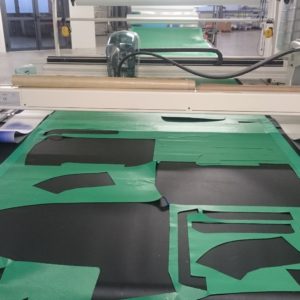

- Cutting of dry and pre-impregnated fabrics (glass, carbon and kevlar) and consumables (vacuum devices)

- Kitting and specific packaging (pocket, chucks, wallets)

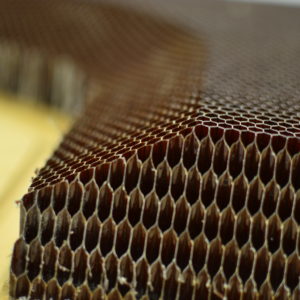

- Cutting of nida nomex and aluminum

- Anchoring, densification and complex machining of nida nomex and aluminum

- Coating / Quilting Composites (RTM Preforms, Thermosetting and Thermoplastics)

- Complete kits of ready-to-drape materials (wiremesh, tedlar, fabrics, glue film, intumescent film, nida + cooking consumables)

- Complete kits of ready-to-cook semi-finished products (dry and pre-impregnated preforms TP or TD, anchored / densified / machined nidas + cooking consumables)

Industrial Means

- 2 Cutting Machines for fabrics and prepregs (LECTRA, ZUND)

- 1 Cold Storage -18°C (40 m3)

- 3 Vacuum compaction tables

- 1 Oven 6 x 2 x 2 m –250°C (FRANCE ETUVE)

- 1 Autoclave Ø2,5xL4,5m -450°C-10 bars (DAXEN)

- 2 Heating press Tunnels

- 2 RTM Injection Machine (ISOJET, ASMA)

- 5 axis Trimming Machine –4,8 x 1,8 x 1,2m (CMS) October 2016

- 2 Preparation Cabins

Composite semi-products

Composite semi-products